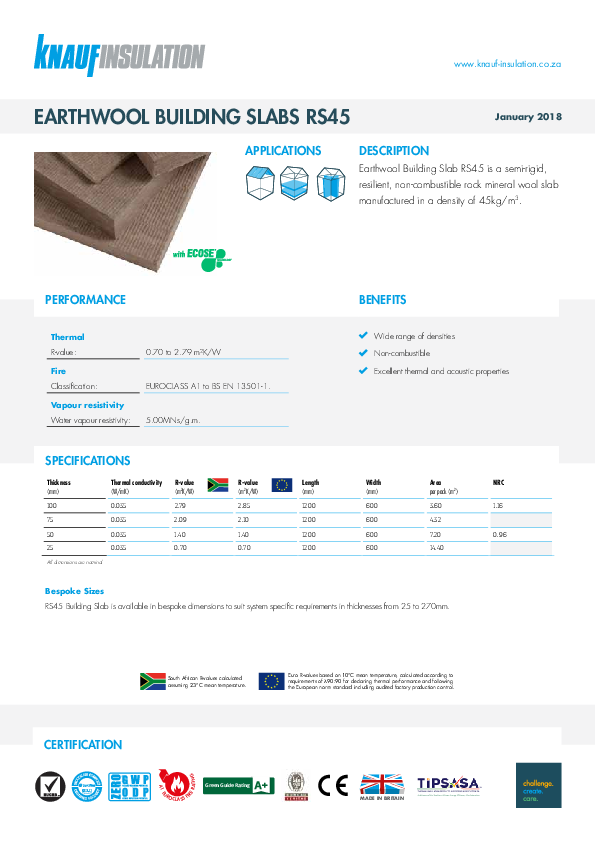

Application

Pitched Roofs at Rafter Level, Ground Floors, Separating Floors, Fabrication, Internal Walls / Partitions, Timber Frame WallsMaterial

Rock Mineral WoolDescription

Rocksilk® RS45 Building Slabs are designed for use in multiple thermal, acoustic and fire applications in both residential and non-residential buildings.

Alternative densities and thicknesses are available on request.

Benefits

- Multi-purpose product range which can be used to insulate a wide range of applications on site - good all-rounder

- Non-combustible A1 Euroclass Reaction to Fire classification

- Excellent thermal performance

- Excellent sound absorption characteristics provide high levels of sound reduction

- Easy to cut with a large bladed knife or serrated saw

- Available up to 270mm thickness

Product

Specifications

| Product Name | Thickness (mm) | Length (mm) | Width (mm) | Product Format | Area per Pack (m²) | Quantity per Pack | Packs per Pallet | Area per Pallet (m²) | R-Value (m²K/W) | Thermal Conductivity |

|---|---|---|---|---|---|---|---|---|---|---|

| Rocksilk® RS60 Building Slab | 25 | 1200 | 600 | 12.96 | 12 | 18 | 155.52 | 0.70 | 0.034 | |

| Rocksilk® RS100 Building Slab | 25 | 1200 | 600 | Un-cut | 8.64 | 12 | 16 | 138.24 | 0.70 | 0.034 |

| Rocksilk® RS45 Building Slab | 25 | 1200 | 600 | Un-cut | 14.40 | 20 | 12 | 172.80 | 0.70 | 0.035 |

| Rocksilk® RS45 Building Slab | 30 | 1200 | 600 | Un-cut | 11.52 | 16 | 12 | 138.24 | 0.85 | 0.035 |

| Rocksilk® RS100 Building Slab | 30 | 1200 | 600 | Un-cut | 7.20 | 10 | 16 | 115.20 | 0.85 | 0.034 |

| Rocksilk® RS100 Building Slab | 40 | 1200 | 600 | Un-cut | 5.04 | 7 | 16 | 80.64 | 1.15 | 0.034 |

| Rocksilk® RS45 Building Slab | 40 | 1200 | 600 | Un-cut | 8.64 | 12 | 12 | 103.68 | 1.10 | 0.035 |

| Rocksilk® RS60 Building Slab | 40 | 1200 | 600 | 8.64 | 12 | 12 | 103.68 | 1.15 | 0.034 | |

| Rocksilk® RS45 Building Slab | 50 | 1200 | 600 | Un-cut | 7.20 | 10 | 12 | 86.40 | 1.40 | 0.035 |

| Rocksilk® RS100 Building Slab | 50 | 1200 | 600 | Un-cut | 4.32 | 6 | 16 | 69.12 | 1.45 | 0.034 |

| Rocksilk® RS60 Building Slab | 50 | 1200 | 600 | 6.48 | 12 | 9 | 77.76 | 1.45 | 0.034 | |

| Rocksilk® RS60 Building Slab | 60 | 1200 | 600 | 5.04 | 12 | 7 | 60.48 | 1.75 | 0.034 | |

| Rocksilk® RS45 Building Slab | 60 | 1200 | 600 | Un-cut | 5.76 | 8 | 12 | 69.12 | 1.70 | 0.035 |

| Rocksilk® RS45 Building Slab | 75 | 1200 | 600 | Un-cut | 4.32 | 6 | 12 | 51.84 | 2.10 | 0.035 |

| Rocksilk® RS60 Building Slab | 75 | 1200 | 600 | 4.32 | 12 | 6 | 51.84 | 2.20 | 0.034 | |

| Rocksilk® RS100 Building Slab | 75 | 1200 | 600 | Un-cut | 2.88 | 4 | 16 | 46.08 | 2.20 | 0.034 |

| Rocksilk® RS45 Building Slab | 100 | 1200 | 600 | Un-cut | 3.60 | 5 | 12 | 43.20 | 2.85 | 0.035 |

| Rocksilk® RS60 Building Slab | 100 | 1200 | 600 | 2.88 | 12 | 4 | 34.56 | 2.90 | 0.034 | |

| Rocksilk® RS100 Building Slab | 100 | 1200 | 600 | Un-cut | 2.16 | 3 | 16 | 34.56 | 2.90 | 0.034 |

| Rocksilk® RS45 Building Slab | 150 | 1200 | 600 | Un-cut | 2.16 | 3 | 12 | 25.92 | 4.25 | 0.035 |

Certification

TIPSASA

TIPSASA

Eurofins Gold

Eurofins Gold

Zero Global Warming Potential

Zero Global Warming Potential

EUCEB

EUCEB

A1 Euroclass Fire Rating

A1 Euroclass Fire Rating

Made in Britain

Made in Britain

Downloads

The download url has been copied to your clipboard

Additional Product Information

- ECOSE® Technology

-

ECOSE® Technology is our revolutionary sustainable bio-based binder used in the manufacture of all of our glass mineral wool products, and the majority of our rock mineral wool products. invented nearly 10 years ago, it is not only unique, but very much central to our sustainability strategy. Our ECOSE® Technology is present in Building Slabs and is just another key benefit of our products.

ECOSE® Technology has 5 key benefits

- A natural binder

- A lower embodied energy

- Proven durability

- Optimum indoor air comfort

- Easy to handle

- Sustainability

-

We care for the people who make our products, the people who use them and the world we all depend on.

Whilst we are dedicated to supplying sustainable high performance insulation solutions for enhanced energy efficiency in buildings, we also continually strive for improvements in our manufacturing and supply chain operations so to improve quality and minimise our impact on the environment. All Knauf Insulation production locations have state-of-the-art manufacturing equipment and meet the highest quality standards as well as they are supported by an ongoing research and development program. All of our products including Building Slabs are sustainably manufactured.

At Knauf Insulation, we have 7 key sustainability considerations:

- to conserve natural resources

- to reduce the evironmental effects of our own processes

- Treating people fairly, along the supply chain

- Delivering our products efficiently

- Building a comfortable and healthy indoor environment

- Performance reporting

- Recognition